If you’ve ever been fortunate enough to try and steer an 80,000 lb construction excavator around, then you’ll quickly realize it’s not something that comes naturally. The amount of skill and finesse it takes to operate these massive machines is nothing short of extraordinary.

Built Robotics is taking this task to a whole new level.

They are taking the principle and technology that other companies are using to build self-driving cars, however molding it to fit a completely different market: Construction.

Introducing Construction Robotics

Built Robotics has built a kit that retrofits construction equipment with hardware like GPS, Wi-Fi, and Lidar, allowing it to autonomously navigate and map and navigate its surroundings. Instead of the company trying to compete with a hyper-competitive trillion dollar industry and build its own bulldozers or excavators, Built is working on making a kit that seamlessly works across popular construction equipment that’s already out on job sites. Their goal is to sell and rent the kit to companies and charge a usage fee whenever the machine is using their kit and in autonomous mode.

How it Works

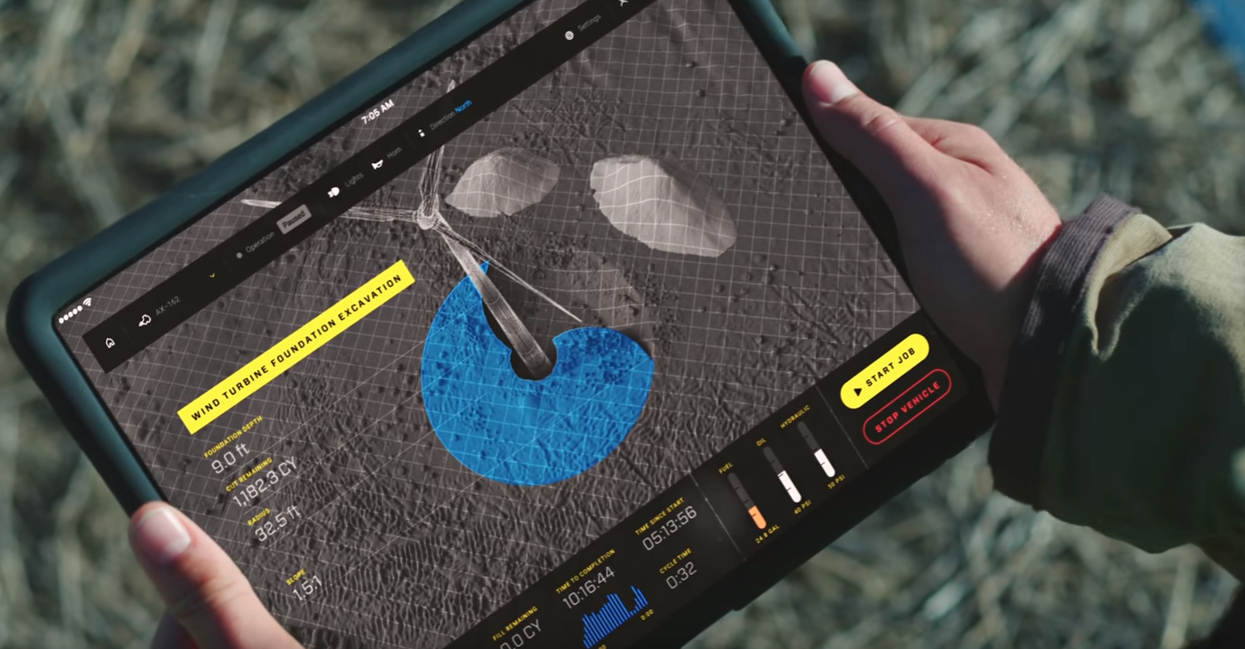

The way it works is that each piece of machinery (for example, a bulldozer) includes their kit, which houses the technology to operate the machine. There are cameras on and around the vehicles that communicates with the operator of the application.

So for example, the operator of the application can draw a red border to tell the machine where it’s allowed to go, and where it can’t. If for any reason the vehicle goes past these borders that the operator sets, the entire machine shuts down.

The cameras and sensors around the vehicles continually survey the landscape for objects that may come to close. If something comes closer than it should be, the machine starts to tip, or even if the onboard sensors identify underground obstructions, power immediately gets cut and the machine stops. As an added fail-safe, there’s an emergency stop button on both the machine and for the operator to use as needed.

Replacing Jobs or Creating Opportunities?

The big question here is how will this technology impact the human workforce that’s been traditionally needed to operate these machines.

The reality is that the construction sector is in the middle of a severe labor shortage, and there aren’t enough humans entering the workforce as it is. In fact, The Associated General Contractors of America asked Congress to support a temporary work VISA program to bring in more workers during March 2019.

While this technology does inevitably has the potential to replace some human labor, it will also create opportunities for those looking to advance in construction field, but on the tech side.

For example – instead of an operator handling 1 single vehicle, they could have the ability to oversee multiple automated fleets of machinery. Simple economics would dictate that the demand (and pay) for these operators would be quite high, as this technology isn’t even mainstream yet. This doesn’t solve the shortage, but does creates more specialized opportunities, while helping to fill the gaps.

The Future of Construction Automation

Built is still in its early days, however it’s already built a research fleet of 7 vehicles, nearing their 10th completed construction project, with over 6,000 hours of operating time, and over $100 million in contracts already signed.

Where there’s change, comes opportunity. You just have to see the angles before others do.